Sheet metal fabrication transforms metal sheets into structural components through systematic processing. Below is the standardized workflow:

Material Selection

Choose metals per design requirements:

Carbon Steel: Cost-effective, high strength (general structures)

Stainless Steel: Superior corrosion resistance (harsh environments)

Aluminum Alloy: Lightweight, high strength (aerospace/automotive)

Verify specifications: thickness, width, length (e.g., thicker plates for high-load components).

Material Inspection

Surface quality: Check for cracks, inclusions, or scale via visual/ultrasonic testing.

Validate chemical composition & mechanical properties (e.g., carbon content in steel, yield strength).

| Method | Application | Advantage |

|---|---|---|

| Shearing | Straight cuts for bulk production | High-speed, dimensional accuracy |

| Example: 2mm steel × 1000mm cut | ||

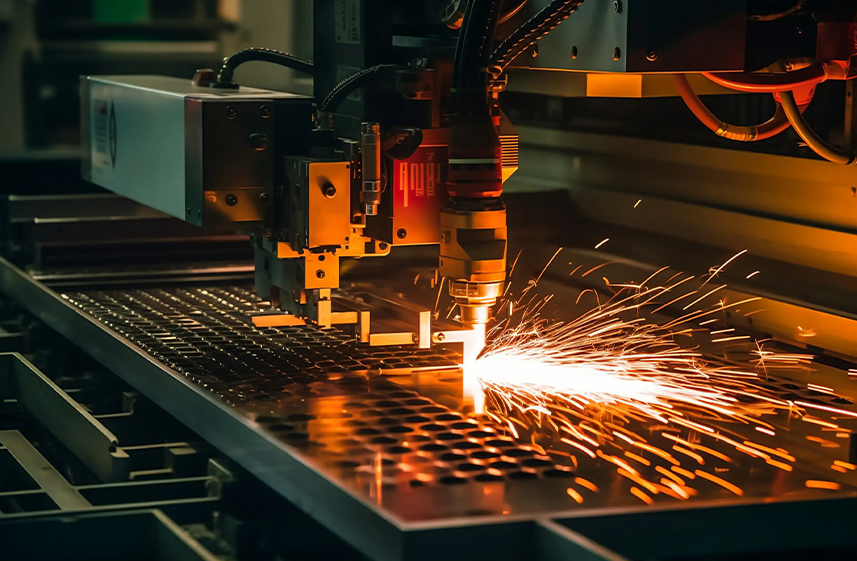

| Laser Cutting | Complex contours (holes, curves) | Precision ±0.1mm, smooth edges |

| Example: Perforated panels | ||

| Plasma Cutting | Thick plates (>10mm) | Rapid processing |

Press Brake Bending

Uses V-dies to form angles (e.g., 90° bends for enclosures).

CNC Bending

Automated multi-stage bending for complex geometries (e.g., chassis components).

| Method | Suitable Materials | Key Features |

|---|---|---|

| TIG Welding | Stainless steel, aluminum | High-quality, aesthetic welds |

| MIG (CO₂) Welding | Carbon steel | Fast, economical |

| Shielded Metal Arc | General steel structures | Portable, versatile |

Process Control:

Pre-weld cleaning (remove oil/rust)

Optimize parameters: current, voltage, travel speed

Post-weld slag removal

Grinding: Remove burrs/weld seams (e.g., smoothing joints).

Painting: Enhance corrosion resistance & appearance (e.g., enclosure coating).

Plating: Zinc/chrome electroplating for critical corrosion protection (e.g., hardware fixtures).

Fit components per engineering drawings (e.g., assembling enclosure panels).

Functional testing: Verify kinematics/structural integrity (e.g., door operation).

Dimensional Check

Tools: Calipers, micrometers, gauge blocks

Tolerance verification (e.g., enclosure dimensions).

Performance Validation

Load testing (structural strength)

Salt spray tests (corrosion resistance).

Cosmetic Audit

Surface defects: scratches, paint uniformity.

Packaging: Wooden crates (large parts) with foam cushioning; cartons (small components).

Transport: Road (short-haul), rail/ocean (long-distance).